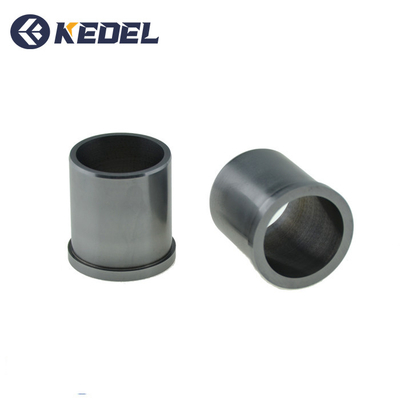

Stripper Guide Tungsten Carbide Bush Oil Press Fit Bushing YN8

Stripper Guide Bushings - Oil, Press Fit Bushing

Headed Press Fit Bush is used when the number of parts to be produced does not necessitate the replacement of the bushings during the life of the Jig. The O.D. of Press Fit Bushings can be supplied with grinding stock for fitting in the Customer's Plant or finish ground to a Press Fit size.

Our Advantages

- Use 100% Raw material, strict incoming inspection

- Overpressure sintering, increasing the densification of the alloy teeth and increasing the 30% life span

- Can be customized according to the requirements of the customer

Production Process

Milling → Proportioning as required → Wet grinding → Dry → Granulation → Press → Sinter → Inspection → Package

Specifications

There are tungsten carbide bushing specifications as below showed, we also accept your inquiry with drawings.

| Model |

Specification |

D |

D1 |

d |

L |

L1 |

| MJP-ZGA-101 |

0016 |

16.0 |

13.9 |

10.32 |

50.8 |

3.18 |

| MJP-ZGA-101 |

0014 |

16.0 |

13.9 |

10.32 |

76.2 |

3.18 |

| MJP-ZGA-101 |

0019 |

17.0 |

15.1 |

10.00 |

49.4 |

4.00 |

| MJP-ZGA-101 |

0018 |

22.0 |

18.88 |

14.29 |

25.4 |

3.18 |

| MJP-ZGA-101 |

0020 |

22.0 |

18.88 |

14.29 |

38.1 |

3.18 |

| MJP-ZGA-101 |

0021 |

22.0 |

18.88 |

14.29 |

50.81 |

3.18 |

| MJP-ZGA-101 |

0022 |

22.0 |

18.88 |

14.29 |

57.15 |

3.18 |

| MJP-ZGA-101 |

0023 |

22.0 |

18.88 |

14.29 |

69.85 |

3.18 |

| MJP-ZGA-101 |

0024 |

21.84 |

20.45 |

17.48 |

30.5 |

2.87 |

| MJP-ZGA-101 |

0025 |

23.4 |

21.0 |

15.00 |

61.0 |

4.00 |

| MJP-ZGA-101 |

0026 |

23.4 |

21.0 |

14.8 |

53 |

4.00 |

| MJP-ZGA-101 |

0027 |

23.4 |

21.0 |

14.8 |

61.0 |

4.00 |

| MJP-ZGA-101 |

0028 |

24 |

21.0 |

16.0 |

61.0 |

11 |

Products Show

Grade Selection Reference Table

| Grade |

Physical & Mechanical Properties |

Recommended Applications |

| YG6 |

Density g/cm³: 14.95

HRA: 89.5

TRS N/mm²: 2580 |

Universal grades widely used in machining tools for cast iron, nonferrous metals and their alloys and nonmetal materials, wear parts, and tools for machining other alloys. |

| YG8 |

Density g/cm³: 14.74

HRA: 89

TRS N/mm²: 2710 |

|

| YG6X |

Density g/cm³: 14.93

HRA: 91

TRS N/mm²: 2480 |

Suitable for the semi-finishing of hard cast iron, nonferrous metals and their alloys, and also suitable for the semi-finishing and finishing of common cast iron and high manganese steel workpieces and for other tools. |

| YG6A |

Density g/cm³: 14.89

HRA: 91.5

TRS N/mm²: 2350 |

|

| YG8C |

Density g/cm³: 14.69

HRA: 87.5

TRS N/mm²: 2850 |

Mainly used for rock drilling, auger tips and well drilling tools and at the same time for drilling stone walls, cementing construction and installation work, and for machining stone materials. |

| YG11C |

Density g/cm³: 14.32

HRA: 86.5

TRS N/mm²: 2940 |

|

Related Products

Our Company

Chengdu Kedel Tools is a professional manufacturer of tungsten carbide products from China. Our company is mainly engaged in research, development and production of various cemented carbide tools. The company has advanced equipment and first-class technical production team to produce and sell cemented carbide products of various shapes, sizes and grades, including cemented carbide nozzles, cemented carbide bushings, cemented carbide plates, cemented carbide rods, cemented carbide rings, cemented carbide rotary files and burrs, cemented carbide end mills and cemented carbide circular blades and cutters, Cemented carbide CNC inserts and other non-standard cemented carbide parts. We are proud that the tungsten carbide parts and components developed and manufactured by Kedel Tools have been exported to North America, South America, Europe, South Africa and Southeast Asia, and our tungsten carbide products are widely used in the following fields: oil and gas industry, coal mining, mechanical seal, aerospace and steel smelting, Metal processing, military industry, new energy industry, packaging and printing industry, auto parts industry, chemical industry.

Production Equipment

Quality Control Equipment

Product Exhibition

Packing & Delivery

Packing Details: Packing press fit bushing, use plastic foam, solid plastic box and carton.

FAQ

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance before shippment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews