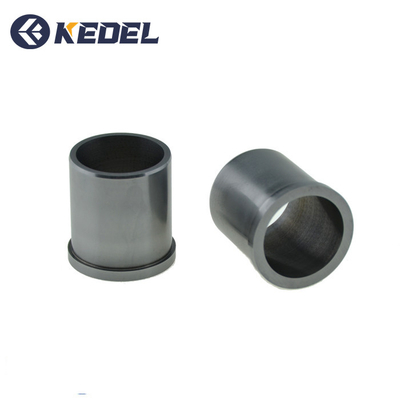

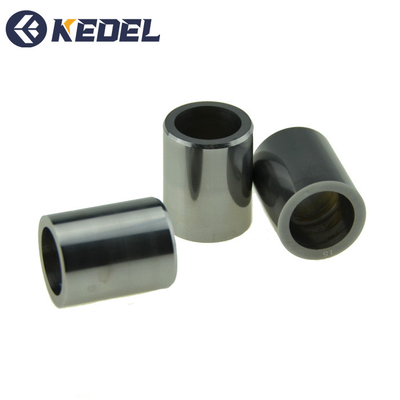

High Precision Drill Tungsten Carbide Sleeves Guide Bushing CNC

Product Description

Our headed press fit bushings are designed for applications where the production volume doesn't require bushing replacement during the jig's lifespan. These tungsten carbide bushings are available with grinding stock on the O.D. for custom fitting at your facility or pre-ground to precise press fit specifications.

Key Advantages

- Manufactured from 100% premium raw materials with strict quality control

- Overpressure sintering process enhances alloy density, increasing lifespan by 30%

- Fully customizable to meet specific customer requirements

Production Process

- Milling

- Precision proportioning

- Wet grinding

- Drying

- Granulation

- Pressing

- Sintering

- Quality inspection

- Packaging

Specifications

Below are standard tungsten carbide bushing specifications. We also accept custom specifications based on your drawings.

| Model |

Specification |

D |

D1 |

d |

L |

L1 |

| MJP-ZGA-101 |

0016 |

16.0 |

13.9 |

10.32 |

50.8 |

3.18 |

| MJP-ZGA-101 |

0014 |

16.0 |

13.9 |

10.32 |

76.2 |

3.18 |

| MJP-ZGA-101 |

0019 |

17.0 |

15.1 |

10.00 |

49.4 |

4.00 |

| MJP-ZGA-101 |

0018 |

22.0 |

18.88 |

14.29 |

25.4 |

3.18 |

| MJP-ZGA-101 |

0020 |

22.0 |

18.88 |

14.29 |

38.1 |

3.18 |

| MJP-ZGA-101 |

0021 |

22.0 |

18.88 |

14.29 |

50.81 |

3.18 |

| MJP-ZGA-101 |

0022 |

22.0 |

18.88 |

14.29 |

57.15 |

3.18 |

| MJP-ZGA-101 |

0023 |

22.0 |

18.88 |

14.29 |

69.85 |

3.18 |

| MJP-ZGA-101 |

0024 |

21.84 |

20.45 |

17.48 |

30.5 |

2.87 |

| MJP-ZGA-101 |

0025 |

23.4 |

21.0 |

15.00 |

61.0 |

4.00 |

| MJP-ZGA-101 |

0026 |

23.4 |

21.0 |

14.8 |

53 |

4.00 |

| MJP-ZGA-101 |

0027 |

23.4 |

21.0 |

14.8 |

61.0 |

4.00 |

| MJP-ZGA-101 |

0028 |

24 |

21.0 |

16.0 |

61.0 |

11 |

Grade Selection Reference

| Grade |

Physical & Mechanical Properties |

Recommended Applications |

| YG6 |

Density: 14.95 g/cm³

HRA: 89.5

TRS: 2580 N/mm² |

Universal grades for machining tools (cast iron, nonferrous metals, alloys, nonmetal materials), wear parts |

| YG8 |

Density: 14.74 g/cm³

HRA: 89

TRS: 2710 N/mm² |

Similar applications as YG6 with enhanced properties |

| YG6X |

Density: 14.93 g/cm³

HRA: 91

TRS: 2480 N/mm² |

Semi-finishing of hard cast iron, nonferrous metals, alloys; finishing of common cast iron and high manganese steel |

| YG6A |

Density: 14.89 g/cm³

HRA: 91.5

TRS: 2350 N/mm² |

Specialized applications requiring high precision |

| YG8C |

Density: 14.69 g/cm³

HRA: 87.5

TRS: 2850 N/mm² |

Rock drilling, auger tips, well drilling tools, stone processing |

| YG11C |

Density: 14.32 g/cm³

HRA: 86.5

TRS: 2940 N/mm² |

Heavy-duty drilling applications |

Related Products

About Our Company

Chengdu Kedel Tools is a professional Chinese manufacturer specializing in tungsten carbide products. We focus on research, development, and production of various cemented carbide tools. Equipped with advanced technology and a skilled production team, we manufacture carbide products in diverse shapes, sizes, and grades including:

- Carbide nozzles and bushings

- Carbide plates, rods, and rings

- Rotary files and burrs

- End mills and circular blades

- CNC inserts and custom non-standard parts

Our products are exported worldwide and serve industries including oil & gas, mining, aerospace, steel production, metal processing, military, energy, automotive, and chemical sectors.

Packing & Delivery

Each carbide bushing is carefully packed using protective plastic foam, sturdy plastic boxes, and reinforced cartons to ensure safe transportation.

Product Benefits

Our carbide bushings offer exceptional hardness, corrosion resistance, wear resistance, and toughness. We specialize in custom non-standard products with pricing based on material selection, production complexity, and order quantity.

Frequently Asked Questions

Q: Are you a trading company or manufacturer?

A: We are the factory with direct manufacturing capabilities.

Q: What is your typical delivery time?

A: Standard delivery is 5-10 days for in-stock items. Custom orders require 15-20 days depending on quantity.

Q: Do you provide samples?

A: Yes, we provide free samples but customers cover shipping costs.

Q: What are your payment terms?

A: For orders under $1000: 100% prepayment. For orders over $1000: 30% deposit with balance due before shipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews