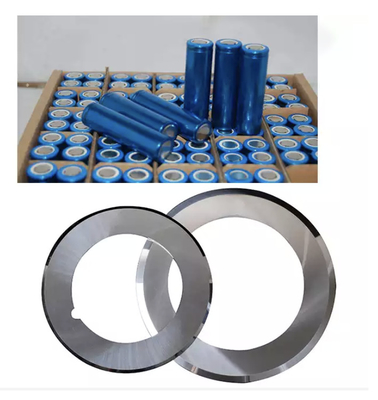

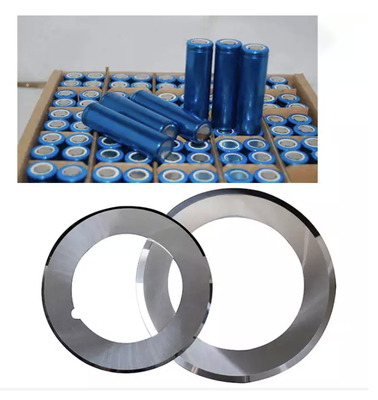

Tungsten Carbide Circular Slitting Knife For Cutting Lithium Battery Electrode Sheet

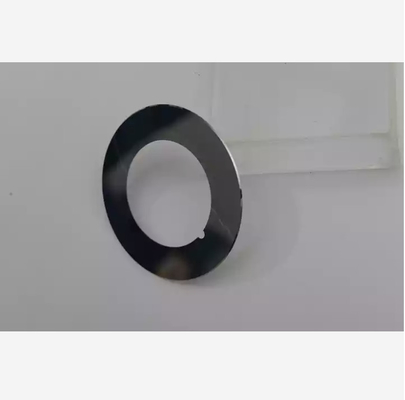

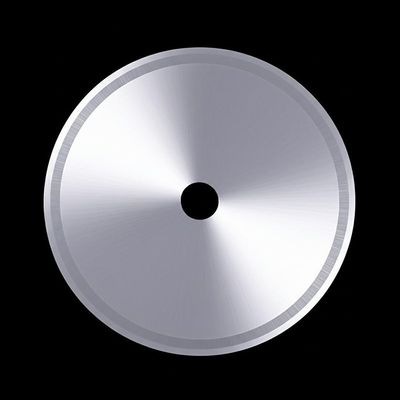

The lithium battery electrode slice slitter is made of cemented carbide powder by pressing and sintering. It has high hardness and strong wear resistance. It is used for the upper and lower circular knives for slitting the positive and negative electrode slices of lithium-ion power batteries and lithium-ion batteries in 3C industry.

From the unique material formula to the precision edge grinding technology, it can better inhibit the cutting burr and prevent adhesion. With long service life and high cost performance ratio, it is an ideal tool for users in the battery industry to reduce cutting costs and improve cutting quality.

Kedel Tools specializes in cutting tools for more than 15 years. It has professional equipment to build a complete carbide tool production line and provide customers with various industrial cutting solutions.

Production Introduction

With the rapid development of the new energy industry, the lithium battery industry is booming, and the demand for lithium battery slitting blades is rapidly increasing. The lithium battery Slitter produced by Kedel Tools has the characteristics of high hardness, strong wear resistance and anti-sticking knife.

Specialized in solving various bad phenomena such as sticking knife, dust, burr, knife back print, wavy edge, and color difference. The full inspection blade is enlarged by 500 times without notch. During the cutting process of the positive and negative electrode pieces of the lithium battery blade, the collapse and burr caused by the poor quality of the cutting edge will cause the battery short circuit problem and form a serious safety hazard.

Chengdu Kedel Tools has many years of experience in the production of cemented carbide industrial tools. All alloy billets are produced by itself. It has a deep understanding of the grinding process of alloy tools. Adhering to the spirit of "craftsman", strictly control the blade size tolerance. The unique edge precision machining technology and 100% automatic edge equipment full inspection process ensure the excellent performance of the lithium battery electrode slice slitter.

Product Features

- Original carbide powder: Hard alloy tungsten steel material, with strong wear resistance

- Long service life: Low friction coefficient and long service life, each blade detects inbound shipments, ensuring quality without worry

- Hardness Guarantee: The raw materials are heat treated, vacuum treated, and the hardness is higher. Heat treatment in your own factory to ensure product stability

- Sharp edge: The knife edge is sharp, smooth, sharp and durable, imported precision processing equipment can process a variety of non-standard products to ensure the precision of the products

Product Application

Main Specifications and Dimensions

| NO. |

Product Name |

Dimensions(mm) |

Edge Angle |

Applicable Cutting Materials |

| 1 |

Slitting top knife

Slitting bottom knife |

Φ100xΦ65x0.7

Φ100xΦ65x2 |

26°,30°,35°,45°

26°,30°,35°,45°90° |

Lithium battery pole piece |

| 2 |

Slitting top knife

Slitting bottom knife |

Φ100xΦ65x1

Φ100xΦ65x3 |

30°

90° |

| 3 |

Slitting top knife

Slitting bottom knife |

Φ110xΦ90x1

Φ110xΦ75x3 |

26°,30°

90° |

| 4 |

Slitting top knife

Slitting bottom knife |

Φ110xΦ90x1

Φ110xΦ90x3 |

26°,30°

90° |

| 5 |

Slitting top knife

Slitting bottom knife |

Φ130xΦ88x1

Φ130xΦ70x3/5 |

26°,30°,45°90°

90° |

| 6 |

Slitting top knife

Slitting bottom knife |

Φ130xΦ97x0.8/1

Φ130xΦ95x4/5 |

26°,30°,35°45°

26°,30°,35°,45°90° |

| 7 |

Slitting top knife

Slitting bottom knife |

Φ68xΦ46x0.75

Φ68xΦ40x5 |

30°,45°,60°

90° |

| 8 |

Slitting top knife

Slitting bottom knife |

Φ98xΦ66x0.7/0.8

Φ80xΦ55x5/10 |

30°,45°,60°

3°,5° |

NOTE: Customization available per customer drawing or actual sample

Product Details

Packing and Delivery

Production Facility

Quality Control

Product Exhibition

Frequently Asked Questions

Are you trading company or manufacturer?

We are manufacturer.

Do you make customized products?

Yes, we often make customized products.

Do you provide free samples?

We can provide free samples, but do not pay freight cost.

How long is your delivery time?

Generally 1-5 days if we have stock, 30 days if the product is customized.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews