Tungsten Carbide Circular Slitting Knife For Lithium Batteries Slitting

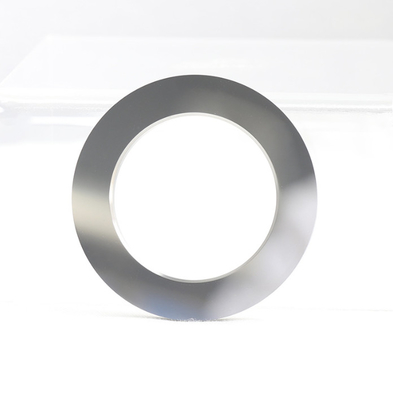

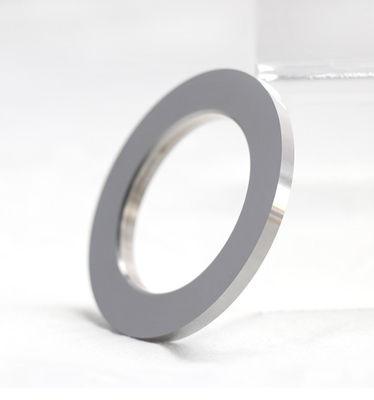

This high-precision tungsten carbide slitting knife is specifically designed for the battery industry, offering exceptional wear resistance and machining precision. The outer circle precision is exceptionally high, with cutting edges undergoing rigorous testing and enlargement inspection.

Production Introduction

Manufactured from cemented carbide powder through pressing, sintering, and fine grinding processes, this slitter features high wear resistance and anti-adhesion properties. It effectively solves common cutting issues including sticking knife, dust, burrs, knife back print, wavy edges, and color differences. Each blade undergoes 500x magnification inspection to ensure notch-free quality.

Product Features

- Hard alloy tungsten steel material with superior wear resistance

- High machining accuracy with thickness precision up to 3 microns

- Extended service life with cutting length up to 20,000 meters

- Excellent blade consistency with minimal burrs and no curling

- Ideal for cutting lithium battery pole pieces, ceramic diaphragms, copper foil, and aluminum foil

- Available in upper and lower knife groups for complete cutting solutions

Technical Process

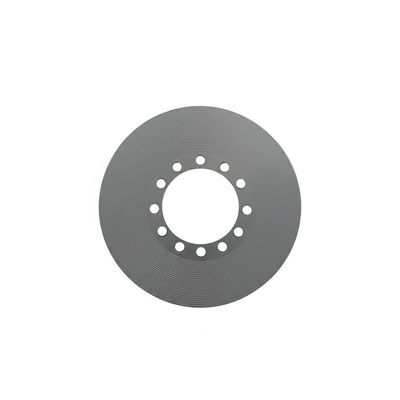

Main Specifications and Dimensions

| NO. |

Product Name |

Dimensions(mm) |

Edge angle |

Applicable cutting materials |

| 1 |

Slitting top knife |

Φ100xΦ65x0.7 |

26°,30°,35°,45° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ100xΦ65x2 |

26°,30°,35°,45°90° |

| 2 |

Slitting top knife |

Φ100xΦ65x1 |

30° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ100xΦ65x3 |

90° |

| 3 |

Slitting top knife |

Φ110xΦ90x1 |

26°,30° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ110xΦ75x3 |

90° |

| 4 |

Slitting top knife |

Φ110xΦ90x1 |

26°,30° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ110xΦ90x3 |

90° |

| 5 |

Slitting top knife |

Φ130xΦ88x1 |

26°,30°,45°90° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ130xΦ70x3/5 |

90° |

| 6 |

Slitting top knife |

Φ130xΦ97x0.8/1 |

26°,30°,35°45° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ130xΦ95x4/5 |

26°,30°,35°,45°90° |

| 7 |

Slitting top knife |

Φ68xΦ46x0.75 |

30°,45°,60° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ68xΦ40x5 |

90° |

| 8 |

Slitting top knife |

Φ98xΦ66x0.7/0.8 |

30°,45°,60° |

Ceramic diaphragm |

|

Slitting bottom knife |

Φ80xΦ55x5/10 |

3°,5° |

NOTE: Customization available per customer drawing or actual sample

Product Details

Packing and Delivery

Applicable Machines

Compatible with machines from BYD, Xicun, Yinghe, Yakang, Haoneng, Qixing, Rongheng, Hongjin, Weihang, Dongli, Qianlima, CIS, Xingheli, Dali, and others.

Frequently Asked Questions

Are you trading company or manufacturer?

We are manufacturer.

Do you make customized products?

Yes, we often make customized products.

Do you provide free samples?

We can provide free samples, but do not pay freight cost.

How long is your delivery time?

Generally 1-5 days if we have stock, 30 days if the product is customized.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!