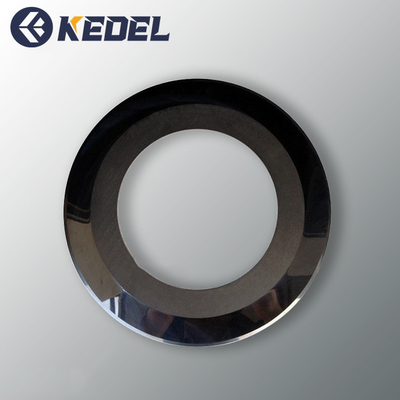

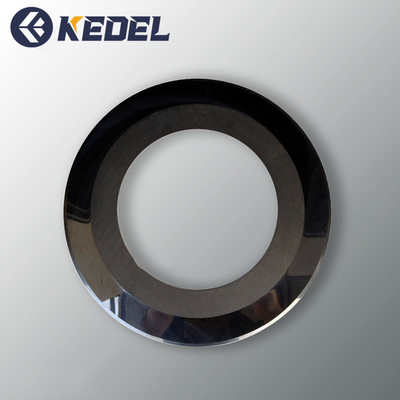

Polishing Tungsten Carbide Slitter Knives for Corrugated Board Cutting

Kedeltool manufactures premium quality corrugated slitter knives for most top-brand corrugated slitter scorers.

Product Specifications

- Material: Tungsten carbide

- Grade: YG12X

- Application: Corrugated paper slitting

- Compatible Machines: BHS, Justu, Fosber, Agnati, Kaituo, Marquip, Hsieh Hsu, Mitsubishi, Jingshan, Wanlian, TCY

Product Description

Corrugated slitter scorers, or corrugated board slitting machines, are used to slit corrugated boards into the proper shape, preparing for further processing. Fast positioning and precision cutting of the slitter scorers and blades during high operation speeds are of great importance.

Tungsten carbide, or cemented carbide, is the ideal material of choice for manufacturing corrugator slitter knives thanks to its toughness and wear & impact resistance, resulting in high precision cutting and long service life.

About Tungsten Carbide (Cemented Carbide)

Tungsten carbide is a mixture of tungsten carbide powder and cobalt powder. The cobalt acts as a binder to bind tungsten carbide particles together. Production involves several processes including wet grinding, drying, granulation, pressing and forming, HIP sintering, and sandblasting. Each material has its own properties, determining the ultimate characteristics of the tungsten carbide.

KEDELTOOL Corrugated Slitter Knife Features

- 100% virgin materials

- Micro-grain tungsten carbide

- Outstanding hardness and toughness

- Excellent wear and impact resistance

- Clean-cut finish

- Extreme durability and extended service life

- Maximized performance

- Minimized downtime

- Varied sizes available

Technical Specifications

| Grade |

Grain Size |

Density (g/cm³) |

Hardness (HRa) |

T.R.S (N/m㎡) |

Application |

| YG12X |

Submicron |

13.9-14.3 |

90.8-91.5 |

3200 |

Suitable for processing cardboard |

Available Sizes

| No |

Sizes (mm) |

| D0001 |

Φ200×Φ122×1.3(No Hole) |

| D0002 |

Φ210×Φ110×1.4(No Hole) |

| D0003 |

Φ210×Φ122×1.4(No Hole) |

| D0004 |

Φ230×Φ110×1.4(No Hole) |

| D0005 |

Φ230×Φ130×1.4(No Hole) |

| D0006 |

Φ250×Φ105×1.4-6×Φ11 |

| D0007 |

Φ260×Φ158×1.5-3×Φ9.2 |

| D0008 |

Φ260×Φ168.3×1.4-8×Φ10.5 |

| D0009 |

Φ260×Φ170×1.4-8×Φ10.5 |

| D0010 |

Φ265×Φ170×1.4-6×Φ11 |

| D0011 |

Φ265×Φ112×1.4-8×Φ10.5 |

| D0012 |

Φ270×Φ168×1.4-8×Φ11 |

| D0013 |

Φ250×Φ140×1.4(No Hole) |

| D0014 |

Φ260×Φ112×1.4-6×Φ11 |

| D0015 |

Φ260×Φ114×1.4-8×Φ11 |

| D0016 |

Φ260×Φ140×1.4(No Hole) |

| D0017 |

Φ260×Φ158×1.4(No Hole) |

| D0018 |

Φ260×Φ158×1.4-8×Φ11 |

| D0019 |

Φ270×Φ168.3×1.4-8×Φ10.5 |

| D0020 |

Φ270×Φ170×1.4-8×Φ10.5 |

| D0021 |

Φ280×Φ168×1.4-8×Φ12 |

| D0022 |

Φ290×Φ112×1.4-6×Φ12 |

| D0023 |

Φ290×Φ168×1.4-6×Φ12 |

| D0024 |

Φ300×Φ112×1.4-6×Φ12 |

Additional Information

We also offer matching diamond grinding stones (sharpening stones) for each slitter knife, according to the required specifications.

Customization Service

Customization services are available. Please provide detailed drawings and expected grades for tailored solutions.

Product Images

Production Facility

Quality Control

Product Exhibition

Exhibition Showcase

Frequently Asked Questions

How to obtain an accurate quotation from Kedel Tools?

Please provide specific material requirements, precise dimensions, and drawings that include tolerances and quantities for different models. This allows us to provide a more accurate quote.

How does our company ensure the quality of its products?

We implement inspection processes from raw material production to finished product grinding, cleaning, and packaging. Each process includes sampling inspection. If a product in any process is not qualified, it will not proceed to the next stage, ensuring finished product quality.

How long does a typical production cycle take?

For stocked products, shipment is immediate. Customized products require 20-25 days for production, depending on processing difficulty.

What is our company's payment method?

We accept wire transfers, L/C, ALIPAY, WEST UNION, and PAYPAL. Standard products require 100% payment before shipment. Custom products require 50% payment before production and 50% before shipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews