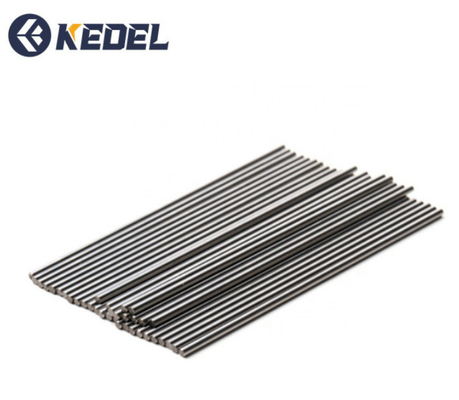

Construction Tool Polished Solid Tungsten Carbide Rod YG6 YG8

Cemented Carbide fine polished solid tungsten carbide rod

Kedel provides custom-made, near-net-shape, premium insert blanks in cemented carbide - also known as Tungsten carbide or solid carbide. Tungsten carbide alloy buttons have their unique working properties.

Product Grades

YG8C: used for the drilling of medium hard and soft rock formation.

YG11C: used for the drilling of hard and super hard rock formation.

Our carbide buttons are exported to Germany, USA, India and Mid-Eeast countries, and enjoying high reputation with good quality.

Carbide Carbide Rod is the raw material for the production of alloy tools such as end mills, drills, reamers, etc. Carbide rods have high hardness and toughness. These cutting tools are widely used in oil drilling and shoveling snow, snow machines and other equipment and used for quarrying, mining, tunnel engineering, and civil buildings.

| Product Name |

China fine polished solid tungsten carbide rod |

| HRC |

HRC45,HRC55,HRC60,HRC6 or higher |

| Grade |

YG8C, YK05, etc |

| Size |

Standard size or customized |

| MOQ |

10PCS |

| Delivery time |

15-25days |

| OEM |

YES |

| Stock |

Rich |

| Production capacity |

50000pcs per month |

| Payment terms |

T/T, PAYPAL, Trade assurance |

Production Process

Milling--Proportioning as required--Wet grinding--Dry--Granulation--Press--Sinter--Inspection--Package

Our Strength

Our experience in tooling design enables us to provide innovative solutions for new applications, safeguarding revenue streams for replacement inserts.

Working in conjunction with our customers we can offer expert advice on specific design criteria ensuring you end up with the best solution for your application. We are not restricted by size or shape.

Our Advantages

- Use 100% Raw material, strict incoming inspection.

- Overpressure sintering, increasing the densification of the alloy teeth and increasing the 30% life span.

- Can be customized according to the requirements of the customer.

Packing Details

Packing tungsten carbide rod, use solid plastic box and carton.

Production Equipment

Quality Equipment

Exhibition

Frequently Asked Questions

1. Are you trading company or manufacturer?

We are manufacturer.

2. Do you make customized products?

Yes, we often make customized products.

3. Do you provide free samples?

We can provide free samples, but do not pay freight cost.

4. How long is your delivery time?

Generally 1-5 days if we have stock, 30 days if the product is customized.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!