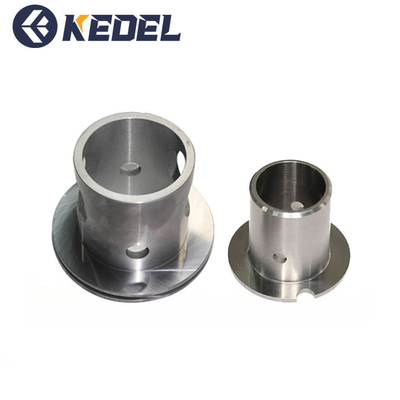

Cemented Tungsten Carbide Sleeves Bushings For Submersible Oil Field

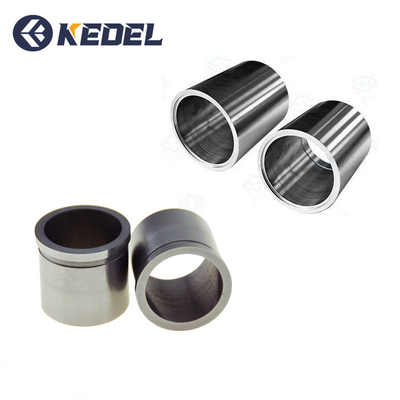

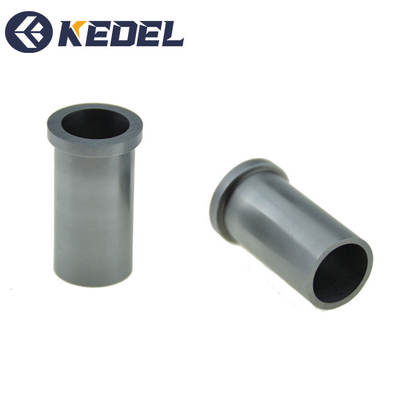

Cemented carbide bushings sleeves are mechanical parts with high wear resistance, strength, and corrosion resistance manufactured through powder pressing, sintering, and precision grinding. These components are widely used in petroleum machinery, coal mining, chemical sealing, and pump valve production.

Applications

Tungsten carbide sleeves serve as protective components with versatile applications. In valve systems, they are installed in valve stem caps to reduce leakage and improve sealing. In bearing applications, they minimize wear between bearings and shaft seats, preventing gap expansion.

These high-strength components withstand prolonged loads and offer excellent chemical stability. They resist alkalis, alcohols, ethers, hydrocarbons, acids, oils, detergents, and water (including seawater). Being odorless, non-toxic, and rust-proof, they are ideal for submerged oil pumps, slurry pumps, water pumps, and centrifugal pumps in petrochemical industries.

Our Advantages

- 100% Raw Material: Produced with pure materials for long service life and stable performance.

- Precision Machining: Processed using high-precision equipment including CNC machining centers, grinding machines, milling machines, and drilling machines.

- Multiple Sizes Available: Custom bearing bushings in various sizes with complete molds and short lead times (7-10 days for samples, 20-25 days for mass production).

- Quality Assurance: Manufactured to stringent standards governing material selection, machining, finishing, inspection, and packaging.

Common Dimensions

| Model No. |

Specification |

OD (D:mm) |

ID (D1:mm) |

Pore (d:mm) |

Length (L:mm) |

Step Length (L1:mm) |

| KD-2001 |

01 |

16.41 |

14.05 |

12.70 |

25.40 |

1.00 |

| KD-2002 |

02 |

16.41 |

14.05 |

12.70 |

31.75 |

1.00 |

| KD-2003 |

03 |

22.04 |

18.86 |

15.75 |

31.75 |

3.18 |

| KD-2004 |

04 |

22.04 |

18.86 |

15.75 |

50.80 |

3.18 |

| KD-2005 |

05 |

16.00 |

13.90 |

10.31 |

76.20 |

3.18 |

| KD-2006 |

06 |

22.00 |

18.88 |

14.30 |

25.40 |

3.18 |

| KD-2007 |

07 |

24.00 |

21.00 |

16.00 |

75.00 |

3.00 |

| KD-2008 |

08 |

22.90 |

21.00 |

15.00 |

75.00 |

3.00 |

| KD-2009 |

09 |

19.50 |

16.90 |

12.70 |

50.00 |

4.00 |

| KD-2010 |

10 |

36.80 |

32.80 |

26.00 |

55.00 |

4.00 |

Grade Chart

| GRADE |

ISO |

DENSITY g/cm³ |

TRS N/mm² |

HARDNESS (HRA) |

APPLICATION |

| YG6A |

K10 |

14.8 |

1750 |

92 |

Excellent wear resistance and strong rigidity, suitable for machining cast iron, non-ferrous metals, wood, and bamboo |

| YG8 |

K20 |

14.7 |

1900 |

89 |

High bending strength, used for processing blades and wear-resistant parts |

| YG15 |

K40 |

14.2 |

2500 |

86.5 |

Used for punching dies, stamping dies, and wear-resistant parts |

| YG15C |

K40 |

14 |

2700 |

85 |

Used for punching dies, stamping dies, and wear-resistant parts |

| YG20 |

K40 |

13.5 |

2750 |

84 |

High bending strength, used for step dies and other stamping dies |

| YG20C |

K40 |

13.4 |

2800 |

82 |

Dies for wear-resistant or impact-resistant applications |

Product Details

Our Production Facility

Production Equipment

Quality Control Equipment

Product Exhibition

Packing and Delivery

Packing Details: PDC carbide cylinder sleeves are packed using plastic foam, solid plastic boxes, and cartons for secure transportation.

Frequently Asked Questions

Q: Are you a trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally 5-10 days if goods are in stock, or 15-20 days if not in stock, depending on quantity.

Q: Do you provide samples? Is it free or extra?

A: Yes, we offer free samples but the customer pays for freight.

Q: What are your payment terms?

A: For payments ≤1000USD, 100% in advance. For payments ≥1000USD, 30% T/T in advance with balance before shipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews