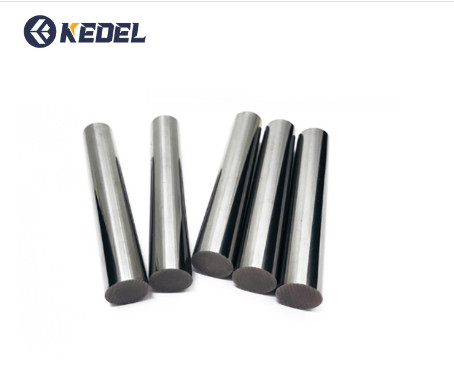

YG10 Ground Tungsten Carbide Round Bars (10mm to 330mm) with HIP Sintering

YG6, YG8, and YG10 solid tungsten carbide round blank bars with lengths from 10-330mm. Our tungsten carbide raw material features 10% cobalt tungsten alloy carbide rod stock (D8x60mm).

We manufacture and stock a comprehensive range of tungsten carbide rods, available with or without holes. Our products feature diameters from 0.3mm to 40mm, with inner holes as small as 0.1mm and lengths up to 340mm. Available in YL10.2, K10, K20, K30, K35, and other grades.

Product Advantages

- Manufactured using 100% virgin raw materials

- Multiple grade options available: YL10.2/YG8/YG6/YG6X/K10/K20 for different applications

- Superior performance characteristics: high hardness, excellent wear/corrosion resistance, good surface roughness

- Standard sizes: diameter 1-6mm * length 330mm, with custom sizes available

- Surface finish options: blank or unpolished per requirements

- Advanced production equipment with complete quality control system

- 100% inspection prior to shipment

- Factory-direct pricing with guaranteed quality from our Chengdu facility

Application Areas

- Paper and packaging industries

- Printing applications

- Non-ferrous metal processing

- Mechanical engineering

- Chemical processing

- Petroleum industry

- Metallurgical applications

- Electronic components

- National defense industries

Technical Specifications

Standard Dimensions

| Diameter (mm) |

Length (mm) |

Tolerance of D |

| 1-3mm |

330 |

h5/h6 |

| 4 |

330 |

h5/h6 |

| 5 |

330 |

h5/h6 |

| 6 |

330 |

h5/h6 |

| 7 |

330 |

h5/h6 |

| 8 |

330 |

h5/h6 |

| 9 |

330 |

h5/h6 |

| 9.5 |

330 |

h5/h6 |

| 10 |

330 |

h5/h6 |

| 11-20 |

330 |

h5/h6 |

| 37 |

330 |

h5/h6 |

Custom diameters and lengths available (ground or unground). Standard inventory includes sizes from Dia1mm to Dia20mm with lengths of 300mm/330mm.

Grade Specifications

| Grade |

Density (g/cm³) |

Hardness (HRA) |

T.R.S (N/mm²) |

Composition (%) |

Grain Size (μm) |

ISO |

| YL10.2 |

14.4-14.6 |

92.5-92.8 |

3800 |

10%Co+90%WC |

0.6 |

K25-K35 |

| YG8 |

14.65-14.85 |

89.5 |

2320 |

8%Co+92%WC |

0.8-1.2 |

K30 |

| YG6 |

14.85-15 |

90 |

2150 |

6%Co+94%WC |

0.8-1.2 |

K20 |

| YG12X |

14.3-14.5 |

92 |

2500 |

12%Co+88%WC |

0.6-0.8 |

|

| YG10X |

14.3-14.7 |

90 |

2200 |

10%Co+90%WC |

0.6-0.8 |

K35 |

| YG15 |

13.9-14.2 |

87 |

2100 |

15%Co+85%WC |

0.8-1.2 |

|

Additional grades and dimensions available based on specific application requirements. Contact us for custom solutions.

Production Process

Our tungsten carbide rods undergo rigorous quality assurance processes:

- All materials tested for purity, density, hardness, and T.R.S. before use

- Each product individually inspected before shipment

Quality Guarantees

- Manufactured using advanced equipment and processes

- High-quality, durable tungsten carbide rods made from 100% virgin raw materials

- Comprehensive in-process and final inspections

- Strict quality control system

- Stable, continuous production capacity

- Free online technical support

- OEM and ODM services available

- Consistent quality for reliable tool performance

- Non-standard sizes manufactured to customer specifications

Available Carbide Rod Types

- Solid carbide rods

- Grinding carbide rods

- Blank carbide rods

- Carbide rods with chamfer

- Carbide rods with single hole

- Custom carbide rods

- Carbide rods with tap

Production Equipment

Quality Control Equipment

Product Exhibition

Frequently Asked Questions

Are you a trading company or manufacturer?

We are a direct manufacturer.

Do you make customized products?

Yes, we frequently manufacture customized products to customer specifications.

Do you provide free samples?

We provide free samples, but customers are responsible for freight costs.

What is your delivery time?

Standard delivery is 1-5 days for in-stock items. Custom products typically require 30 days for production.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews